Find Your Motorcycle Bearings and Maintain Them

Safety is always the foremost concern for us motorcycle owners, and the only way to keep our motorcycles safe is with regular maintenance. A service manual can seem daunting at first, but it has all of the information you need. Of course, the internet is also a great resource, but having a service manual is always a great way to double-check an internet article’s credibility. Most moving components on a motorcycle tend to wear out over time, so you need to check them. Maintaining motorcycle bearings is one important part of a motorcycle that needs attention and upkeep for biker safety will be addressed here.

Bearing Maintenance

Bearings on your motorcycle are items that need to be checked in the wheels and steering neck at regular intervals. On most new models, bearing clearances do not require adjustment. These models contain sealed bearings. This means the bearing, grease and seal are all one piece and usually do not need to be shimmed or adjusted. The problem with sealed bearings is that they can never be re-greased, which causes them to fail over time. In this case, they need to be removed and replaced. For most wheels with sealed typed bearings, a special tool (a puller with a collet) is recommended. This tool expands inside the bearing and pulls against the wheel hub using a long threaded rod. The same tool can be used to install a new bearing. The bearing should be square; this will ensure that if an axle or steering stem passes through the bearing, it will not bind.

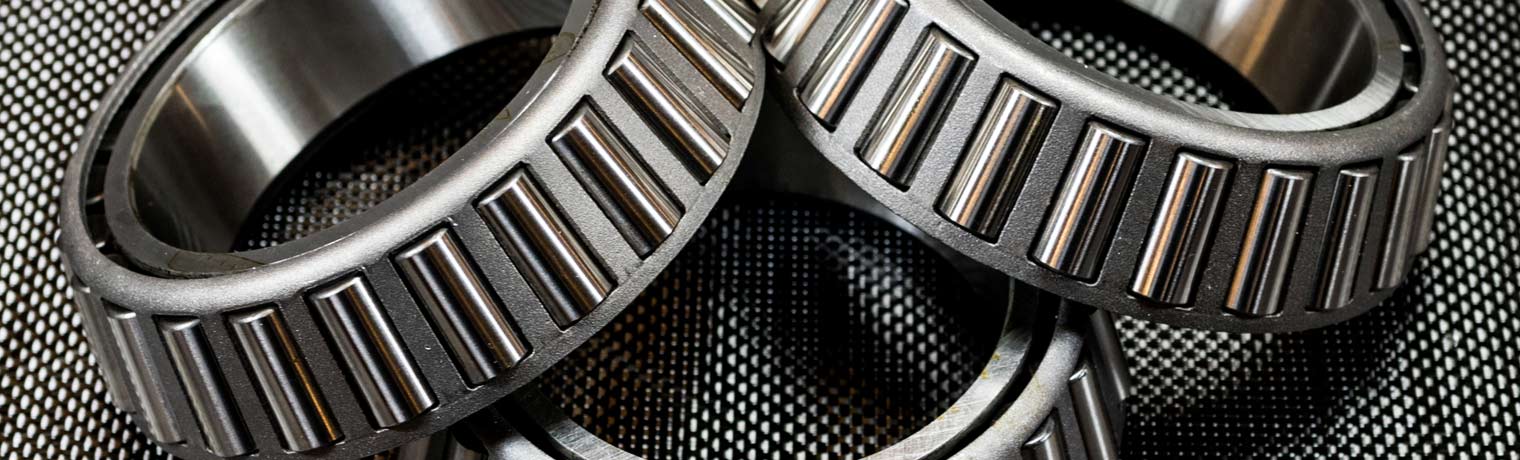

On some older motorcycles, the wheels and steering will have ball or taper styled bearings. Taper bearings perform well and are very durable. Ball bearings on your motorcycle work just fine, but require more maintenance and are much harder to replace and/or clean and reinstall. The best trick for putting all the steel balls back is to use grease as a binder (sticky grease holds the balls in place). You can convert most ball bearing applications over to a taper bearing. This requires some work, but it is the recommended course of action.

This site and articles contained herein are provided for general informational purposes only and are not a substitute or intended as professional advice. Please be sure to refer to your owner’s manual or consult a mechanic for information specific to your motorcycle. The information contained on this site and articles contained herein are provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness or timeliness and without any warranties of any kind whatsoever, express or implied. Rider Insurance Company and its affiliates (together, “Rider”) assume no responsibility for any errors or omissions in the content of this site and articles contained herein. Any action taken upon this information is strictly at your own risk and Rider will not be liable for any losses or damages in connection with your use of this site and articles. Additional terms and conditions apply and are available at https://www.rider.com/plymouth-rock-assurance-general-terms-and-conditions/.

Taper Bearings

A taper bearing uses balls or rollers in a cage on a taper to keep the axle square to the hole. You will need to install a race to accept a bearing. Never install just a bearing without changing the race. They are machined to each other and thus, so need to be installed together. Remove the old oil seal (pry with a screw driver or pry bar). Races must be driven out of a wheel hub or steering neck using a special driving tool. They can be hammered out carefully so as not to damage anything else. You can flip the old race backwards and use it to help drive the new race in. Make sure the race is square to the hole it is being driven into. An old trick to install races is to freeze the race in a freezer and lightly heat the wheel hub.

Shim Adjustments

Some taper bearings require shims. The best way to get your proper shim adjustment is to install the bearing dry with no grease. For a wheel, bring the whole assembly to a bench. Take the axle, spacers, new bearings on your bike and the wheel itself. Using a large vice, you can clamp the axle, install the wheel spacers, and slide the taper bearing onto the axle; then slide the wheel on. You will usually find that a spacer is between the bearings that will slide next along with the shims. The amount of shims needed depends on the model of the motorcycle. Look for these specifications in your service manual. The other bearing can be slid on, wheel spacers dropped down, and the axle nut can be torqued to the manual’s specifications.

To check end play (the amount of free space between bearing and race) use a dial indicator. Attach the magnet base of the dial indicator to the brake rotor and the tip of the indicator on the axle nut. Wiggle the wheel up and down and it should register the amount of endplay. If there is too much endplay, add another shim; if there is too little end play, remove a shim.

You can disassemble everything and grease the bearings. Pack the bearings with grease to remove any little air pockets. Lube the races and axle with generous amounts of grease. If you like, hammer a new oil seal into one side of the wheel. Place the bearings, spacer and shims inside the hub. Then install the other oil seal. The whole wheel assembly can be reinstalled into the motorcycle and the axle nut can be torqued down. The wheel should spin freely. You can install a steering bearing virtually the same way, but it may have some different components.

Check the end play in bearings whenever the service manual calls for it. If end play exceeds the amount allowed, the bearings and races should be replaced. Always play it safe when it regards bearings or wheels. Never attempt to do bearing maintenance without complete confidence in the job. When in doubt, consult a professional technician. As always, practice safe riding.